In this article, we want to talk About Waffle Slab or Ribbed Slab Construction Procedure . Join us .

What is Waffle Slab or Ribbed Slab?

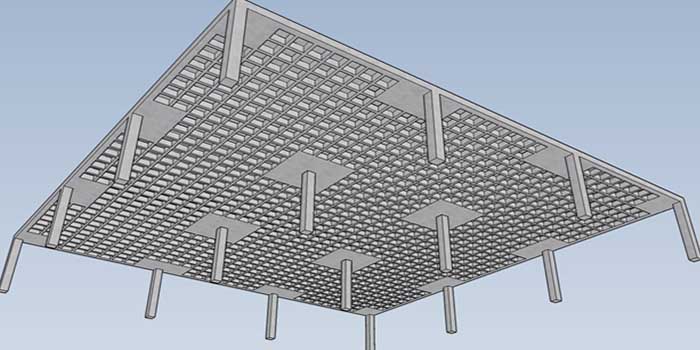

Waffle slab or ribbed slab is a structural component which is plain on its top and contains grid like system on its bottom surface. The top of ribbed slab is normally thin and the bottom grid lines are generally ribs which are laid perpendicular to each other with equal depth. Waffle slab has two directional reinforcement.

Characteristics of Waffle Slabs

- Waffle slabs are generally suitable for flat areas.

- Volume of concrete used is very less compared to others.

- The reinforcement in the waffle slab is provided in the form of mesh or individual bars.

- Separate excavation for beams is not required in case of waffle slab.

- The bottom surface of slab is looks like waffle which is obtained by using cardboard panels or pods etc.

- The thickness of waffle slab recommended is 85 to 100 mm while the overall depth of slab is limited to 300 to 600 mm.

- The width of beams or ribs provided in waffle slab are generally 110 to 200 mm.

- Spacing of ribs recommended is 600 to 1500 mm.

- Reinforced waffle slabs can be constructed for the span up to 16 meters while beyond that length prefabricated waffle slab is preferable.

- Waffle slab is good against shrinkage and it is lower than stiffened rafts and footing slabs.

- Waffle slab requires only 70% of concrete and 80 % of steel from the concrete and steel used for stiffened raft.

Waffle Slab Construction Procedure

The construction of waffle slabs can be done by three ways as follows.

- In-situ

- Precast

- Prefabricated

In-situ waffle slabs are constructed by pouring concrete in the site or field with proper arrangements. In case of precast waffle slab, slab panels are casted somewhere and they are joined together with proper reinforcement and concrete is filled.

Benefits of Waffle Slab Construction

- Waffle slabs are used for larger span slabs or floors and used when there is limited requirement for number of columns.

- The load carrying capacity of waffle slab is greater than the other types of slabs.

- They provide good structural stability along with aesthetic appearance. Hence, it is constructed for airports, hospitals, temples, churches etc.

- The waffle slab can be made of concrete or wood or steel among those concrete waffle slab is preferred for commercial buildings and other two are preferred for garages, decorative halls etc.

- It has good vibration control capacity because of two directional reinforcement. So, it is useful for public buildings to control vibrations created by movements of crowd.

- Waffle slabs are lightweight and requires less amount of concrete, hence it is economical.

- Construction of waffle slab is easy and quick with good supervision.

- Concrete and steel volume required is small, hence, light framework is enough for waffle slab.

- Several services like lighting, plumbing pipes, electrical wiring, air conditioning, insulation materials etc. can be provided within the depth of waffle slab by providing holes in the waffle bottom surface. This system is called as Holedeck.