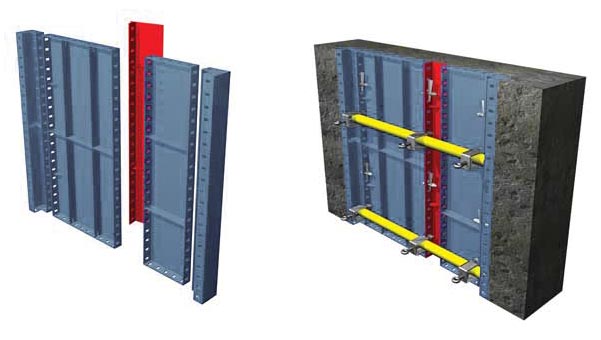

Modular formwork system is very economical and cost-effective due to it being diversely utilized in the entire array of concrete structures such as walls, columns, beams, slabs, and foundations.

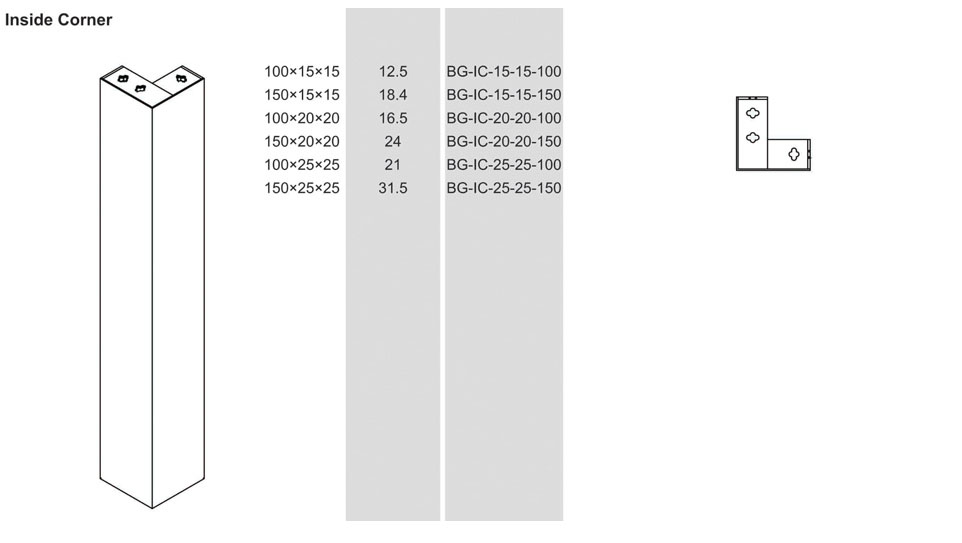

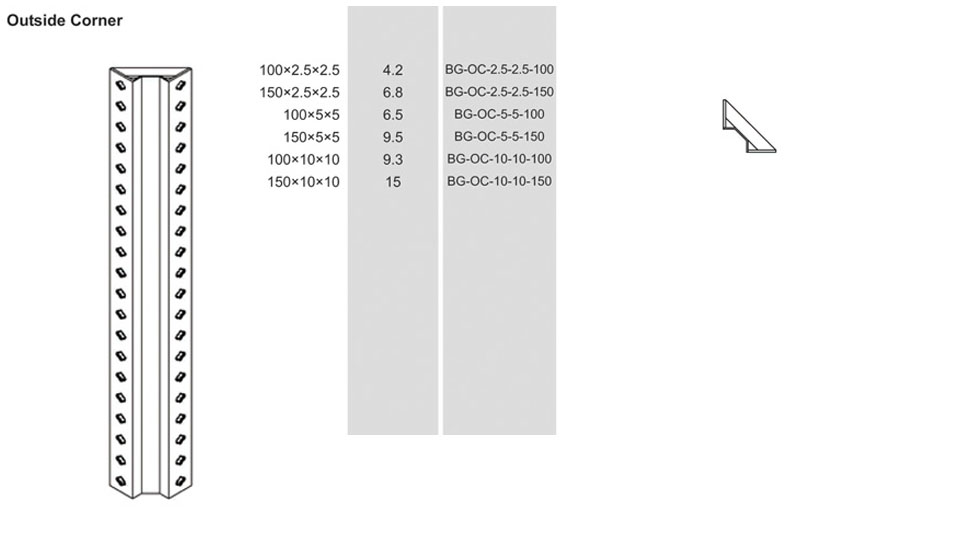

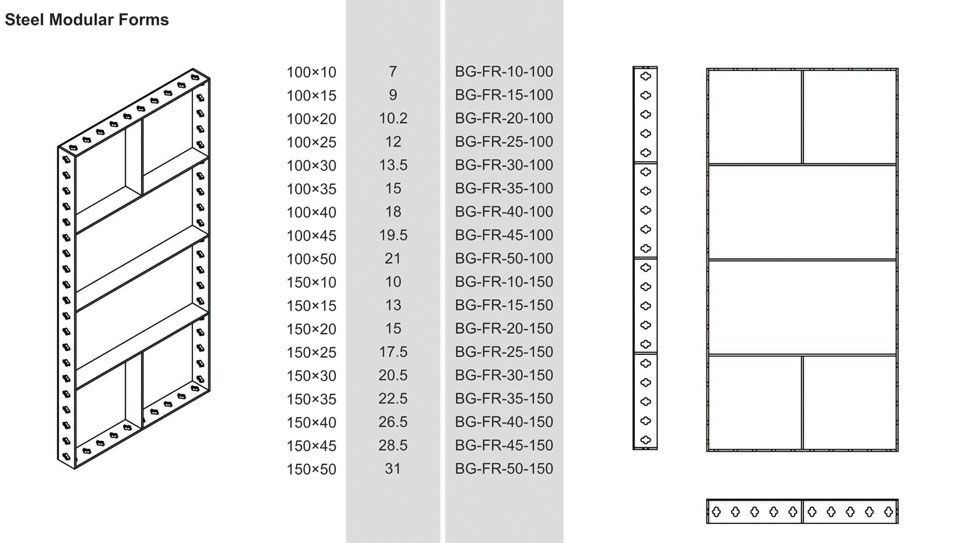

Modular formworks which are also called multi-purpose formworks are designed and manufactured based on multiples of 5 centimeters in width. These formworks have the most usage in mantling various parts of a concrete structure and get produced in different sizes and dimensions.

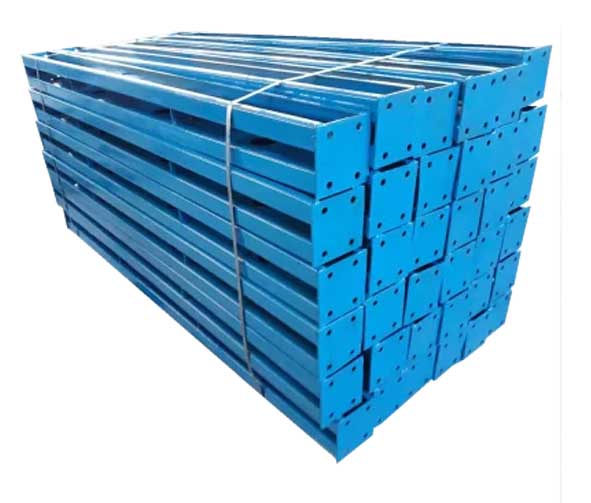

InternationalEMC provides formwork for various concrete structures such as walls, ceilings, concrete pillars, slabs, and foundations. We use the best steel sheets for our production.

The quality of steel sheets is St37. Their standard is complying with DIN 17100/80 of Germany. These steel sheets are specially for building projects and concrete structures. As you know this kind of steel is more resistant to impact. So you can use your formwork in more projects.

Modular formworks are manufactured in widths of 10, 15, 20, 25, 30, 35, 40, 45, and 50 centimeters and lengths of 100, 150, and 200 centimeters. They can also come in other dimensions based on the client’s order