In this article, we want to talk About Waffle Slab (Ribbed Slab) Construction . Join us .

GPRS is the nation’s largest private subsurface locating company.

GPRS is the company that provides concrete scanning, utility locating, leak detection, and video pipe inspection services.

Our dedication to safety has helped us achieve an over 99.8% subsurface damage prevention scanning rate on hundreds of thousands of scanning and location projects.

GPRS has unparalleled accuracy, and as a company, we want to raise the industry standard. To help push the industry forward, GPRS is releasing articles about our training methodology.

This article will review our training documentation and methods of ribbed and waffle slab scanning.

Ribbed and Waffle Slabs

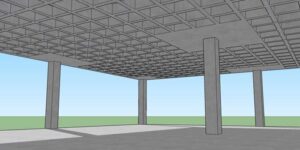

Ribbed slabs could also be called joist slabs or beam and joist slabs. These slabs have narrow concrete beams (joists) that span between larger, traditional concrete beams in the column lines. The joists are often 2’ to 3’ on center.

The structural support from the joists allow the slab to be as thin as 2”-6”. These slabs are still poured onsite using rebar like a traditional rebar slab but most of the structural support is in the joists.

The slab is thinner and could contain minimal reinforcing such as just wire mesh or rebar that is spaced further than a traditional, flat slab.

The rebar in the slab should be marked but the primary goal when scanning these slabs is to identify the joists as no core drilling should take place through a joist.

Waffle Slab

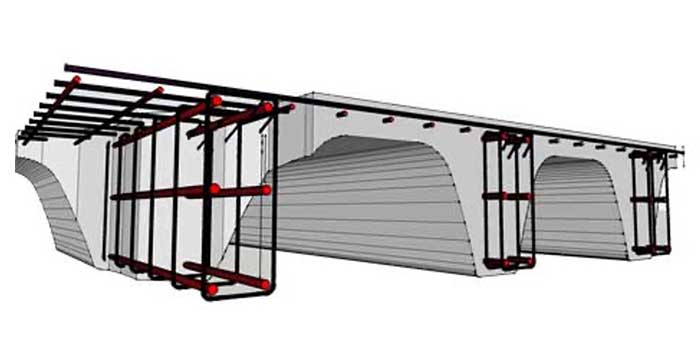

A waffle slab is just a two-way joist system. The slabs shown below do not have larger beams at the columns due to the added strength of the waffle system.

How to Diagnosing a Ribbed Slab

The slab being less than 6” thick is usually the first clue. A traditional rebar slab will be at least 6” thick. A slab that appears to be less than 6” could actually be a topping slab with something like foam below and sitting on top of a structural slab.

A topping slab on foam can fool the GPR technician into thinking that the bottom of the slab is being seen when, in fact, only the topping slab is being seen and the structural slab is not being seen at all. The general guideline is, if the slab is less than 6” thick then it is probably a topping slab unless a pattern of joists or beams can be confirmed which would allow for a thinner slab.